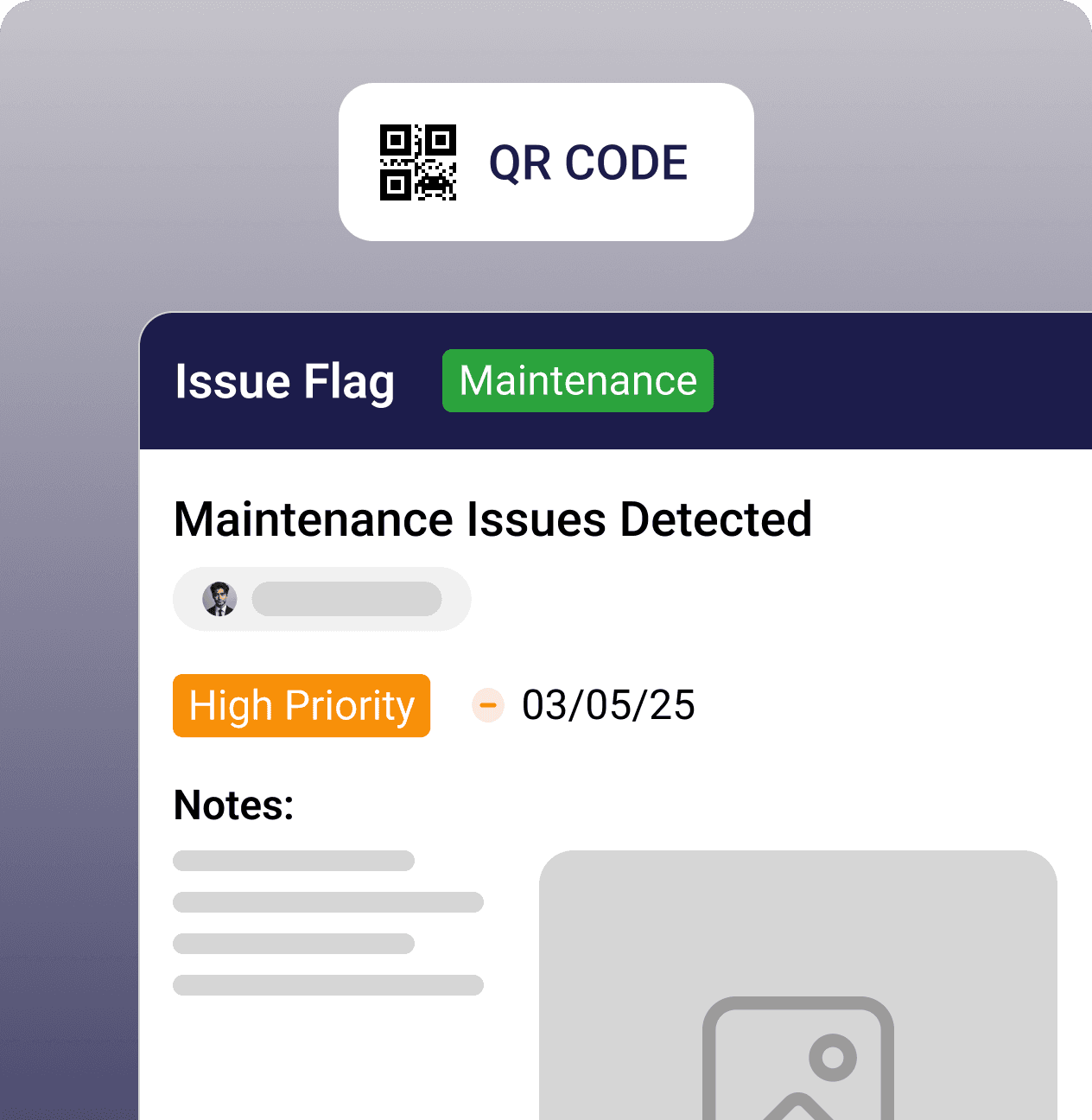

1. Capture work orders instantly

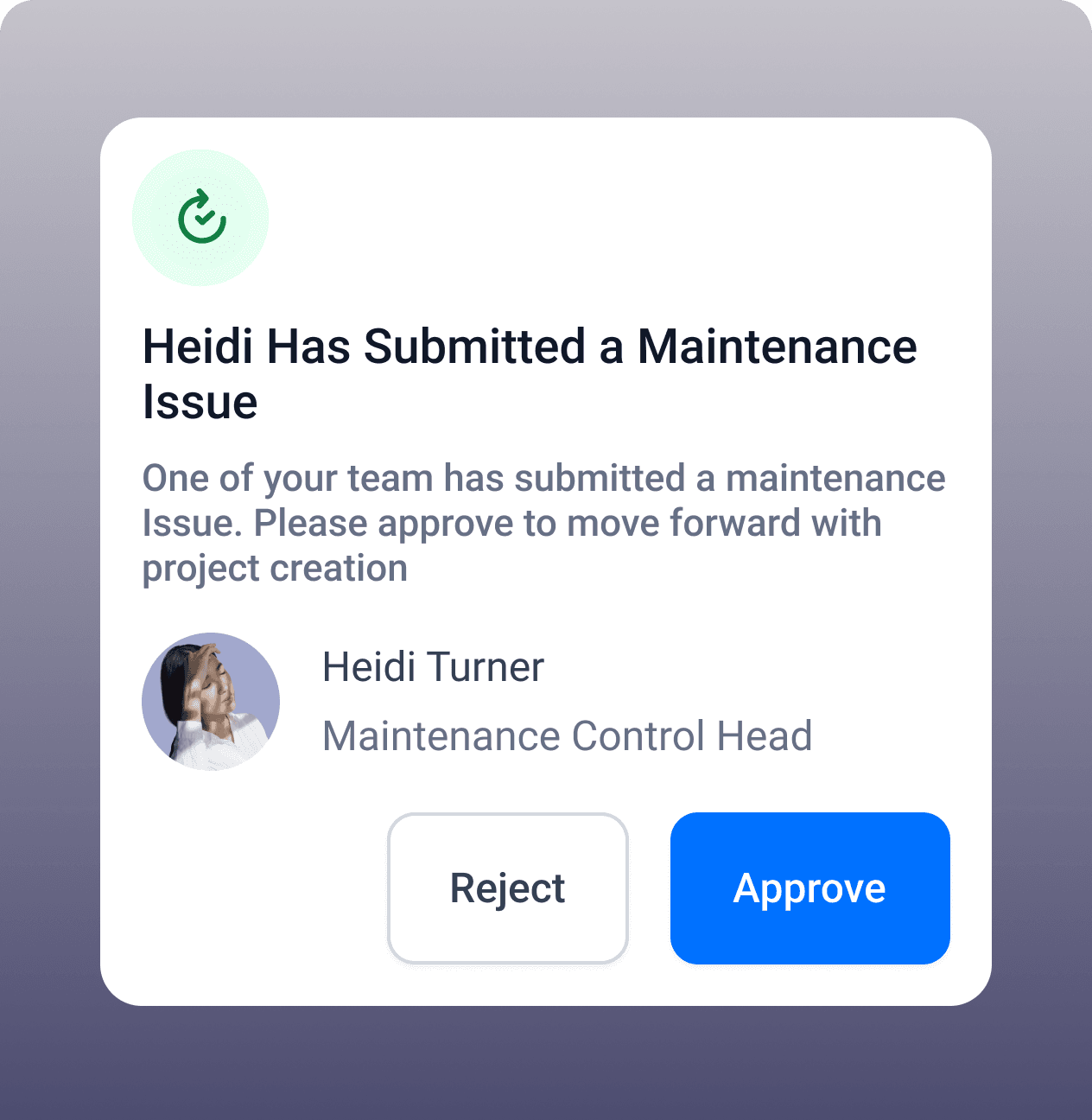

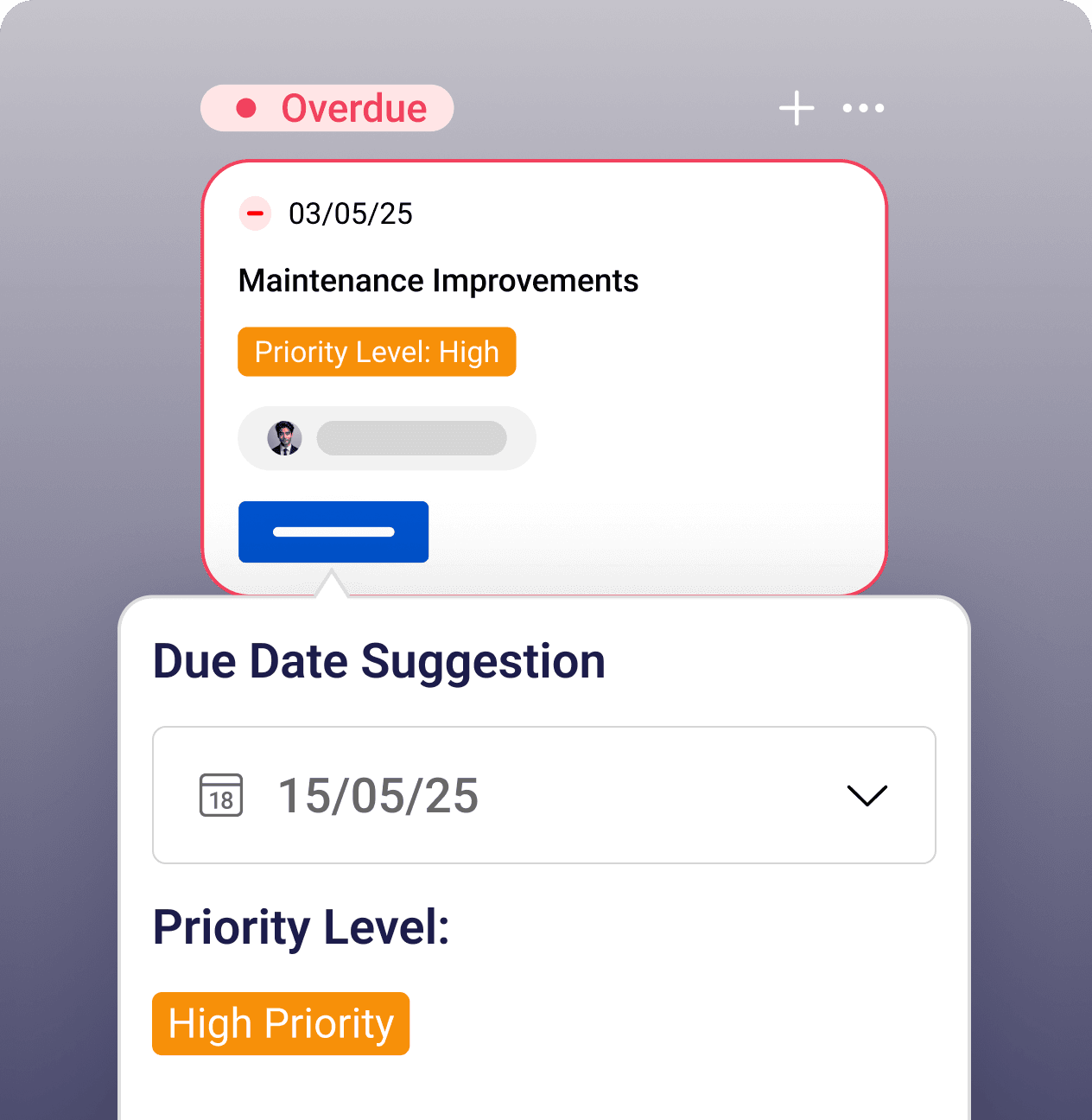

Work orders are created automatically when an operator tags an issue or when a scheduled PM is due. Each ticket includes rich data like photos, location, and equipment ID, eliminating guesswork.

LeanSuite replaces radio calls and paperwork with a transparent, digital process. From the first flag to the final fix, your team has a clear, accountable path to resolution.

Work orders are created automatically when an operator tags an issue or when a scheduled PM is due. Each ticket includes rich data like photos, location, and equipment ID, eliminating guesswork.

The moment a work order is created, it appears on a live maintenance dashboard. Track status, technician assignments, and your entire backlog in one central place.

Technicians can document the fix, log parts used, and close out work orders from any device. The entire process is documented, building a searchable repair history for every asset.

LeanSuite’s advanced features use AI and data visualization to give your technicians better information and give your leaders a clearer view of facility health.

Get rid of outdated maintenance whiteboards. With our new Floor Plan feature, you can upload your facility layout and LeanSuite will automatically build a live equipment health map to show you which machines have the most open work orders.

Help operators give you better information. With our new Lean AI feature, operators can simply snap a photo of a fault, and our AI will analyze the image to automatically write a detailed description, ensuring your technicians arrive with the right tools and context.

LeanSuite brings intelligent automation to your maintenance management process, ensuring rapid response and clear ownership.

Categorize every issue for better tracking and analysis. Our flexible tagging system allows you to create custom tags for any process or department.

Flag equipment that is down and not running production.

Identify opportunities to create new Preventive Maintenance tasks.

Tag maintenance issues that pose a direct safety risk.

Flag equipment issues that are causing product defects.

LeanSuite connects your maintenance program to your broader continuous improvement ecosystem.

Is the same breakdown happening over and over? With one click, escalate a recurring problem into a formal Kaizen or A3 project to address the root cause.

Integrate with your inventory or ERP system to automatically log spare parts used during a repair, ensuring accurate inventory counts.

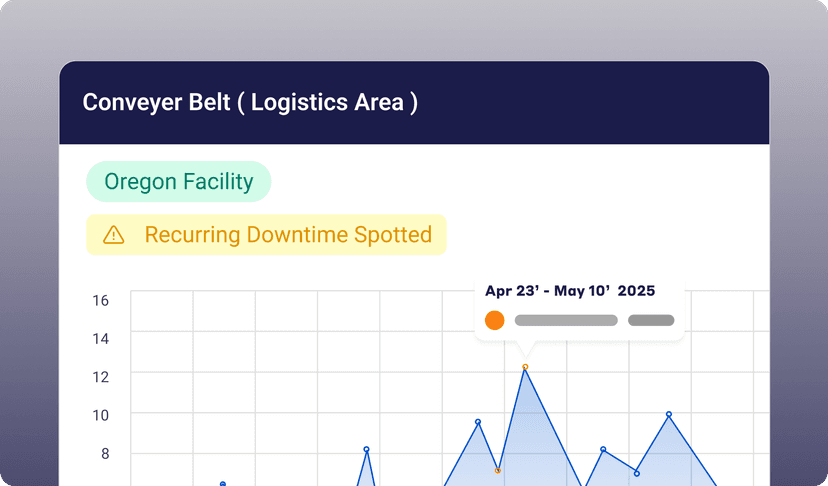

Use built-in dashboards to analyze MTTR, MTBF, and other key metrics by machine or line. Identify your worst-performing assets and make data-driven decisions.