Tired of Kaizen events ending with stale spreadsheets and forgotten gains? You've rallied the team, run the event, and felt that initial surge of progress—only to watch momentum evaporate as data turns into a buried mess. Factories lose up to 20% potential ROI when metrics lag behind shop floor reality, turning hard-won improvements into vague memories. These 5 battle-tested methods deliver live tracking that proves wins instantly, without needing fancy tech or IT approvals. No more "trust me, it worked" reports.

Let's turn raw data into daily decisions that stick. Imagine operators glancing at a board, spotting trends mid-shift, and adjusting on the fly. That's the power of real-time metrics done right.

Method #1: Visual Floor Boards for Instant Visibility

Paper logs gather dust while production lines grind non-stop, but physical or digital floor boards bring metrics to life right where the action happens. This low-tech powerhouse transforms abstract numbers into something operators can touch, move, and own. Teams that see their OEE climb from red to green mid-shift don't just report data—they live it, sparking ownership that spreadsheets never could.

Quick Setup Steps:

- Select 4 core KPIs: OEE, defects per hour, cycle time, and uptime—keep it laser-focused.

- Use magnets or sticky notes: Red for issues, green for wins, updated every shift in 2-minute huddles.

- Photo-share daily: Snap progress pics sent straight to leadership via group chat for instant buy-in.

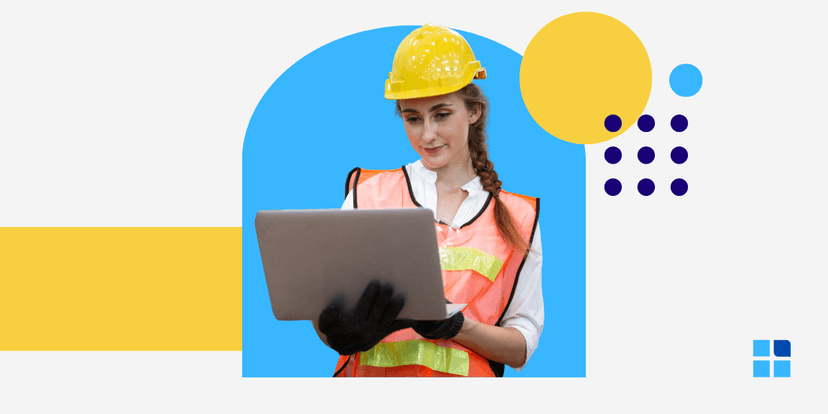

Method #2: Mobile Pulse Checks Mid-Event

End-of-day reports capture yesterday's news, but the real magic happens mid-shift when operators spot a cycle time drop or defect pattern emerging. Mobile pulse checks turn phones into real-time data capture devices, letting you catch gains as they unfold and pivot before problems compound. This keeps energy high and proves Kaizen's impact while it's still fresh.

Quick Setup Steps:

- Launch a 3-tap survey: "Time saved today? Issues fixed? Ideas sparked?"

- Timestamp everything using phone notes, Google Forms, or a shared notepad app.

- Hourly roll-up huddles: Quick voice review reveals trends faster than any spreadsheet could.

Think of it as the shop floor's heartbeat monitor—small inputs, massive insights.

Method #3: Before/After Process Timing

Vague "it feels faster" claims crumble under scrutiny, but hard before/after numbers silence every doubter and light up ROI discussions. By timing key processes live from day one, you baseline reality then watch improvements stack up visually. This method turns skeptics into evangelists when they see the math: 15% faster cycles = thousands in monthly savings.

Quick Setup Steps:

- Day 1 baseline: Stopwatch 20 full cycles, calculate the average.

- Daily re-measure: Same process, log variances in a simple running tally.

- Visualize gains: Hand-drawn bar chart shows "% improvement = dollars saved."

Numbers don't lie. Your event's story tells itself.

Method #4: Gamified Leaderboards

Dry metrics bore even the most dedicated teams, but gamified leaderboards turn tracking into friendly competition that fuels sustained engagement. Operators chase points for fixes and ideas, creating a viral energy where data entry feels like winning. What starts as a whiteboard tally ends up driving 30% more actions per event.

Quick Setup Steps:

- Simple point system: +15 points for beating metric targets, +25 for implemented ideas.

- Live whiteboard ranking: Update after every break to keep the buzz alive.

- Weekly rewards: Coffee cards or shoutouts for top teams—motivation on a budget.

Competition uncovers hidden potential. Spreadsheets can't compete with that thrill.

Method #5: Threshold Alerts (Low-Tech Version)

Silent failures sneak up and erase gains overnight, but threshold alerts flag drops the moment they happen, triggering instant fixes. Whether it's a buzzer for OEE dips or a visual alarm, this keeps your Kaizen event proactive rather than reactive. Patterns emerge in days, not weeks.

Quick Setup Steps:

- Define red-line rules: OEE under 85% triggers an audible or visual alert.

- Immediate 5-minute huddle: Assign fixes on the spot.

- Log every resolution: Weekly review spots recurring culprits.

Common Pitfalls to Dodge:

- Metric overload: Max out at 5 KPIs or analysis paralysis kicks in.

- Skipping Day 1 baselines: Without them, gains dissolve into "guesses."

- Ignoring soft metrics: Morale and engagement drive 40% of long-term sustainability.

- Bonus Win: Layer issue tagging atop metrics to uncover root causes automatically.

Live metrics don't just track Kaizen—they make it addictive, embedding continuous improvement into your factory's DNA. Pro Tip: Scale this effortlessly with purpose-built tools like LeanSuite's Kaizen Module. It auto-pulls OEE, yields, and leaderboards straight from frontline inputs into real-time dashboards—no manual data entry, just pure visibility.

Choose one method today. Deploy it Monday. What's currently killing your Kaizen tracking? Share your biggest headache below—we're all in this together!

LeanSuite: A complete lean manufacturing software

Schedule Demo