78% of Manufacturing Hazards Go Unreported: Here's Why

Manufacturing facilities operate under a dangerous illusion. Safety programs exist. Incident reporting systems are in place. Training happens regularly. Yet the majority of hazards that could prevent catastrophic injuries never surface until someone gets hurt.

Research indicates that approximately 78% of workplace hazards in manufacturing environments go unreported by frontline workers. This statistic represents more than a documentation gap. It reveals a fundamental breakdown in safety visibility that transforms preventable risks into inevitable incidents. When hazards remain invisible to management, the opportunity to intervene disappears.

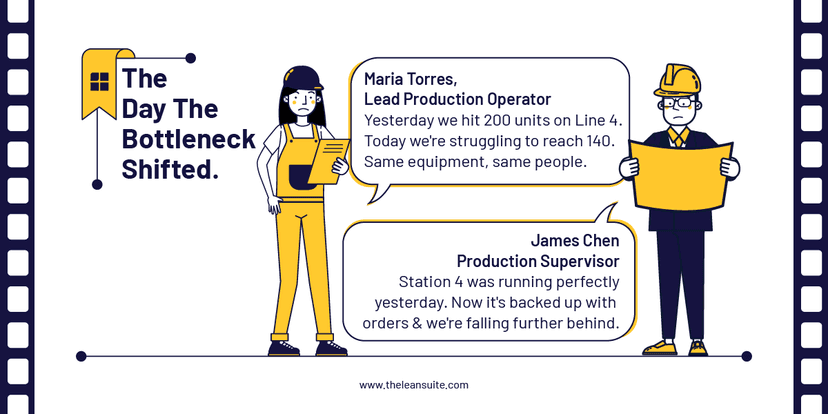

The Visibility Crisis in Manufacturing Safety

Traditional safety metrics create a false sense of security. Facilities track lagging indicators like injury rates, lost-time accidents, and OSHA (Occupational Safety and Health Administration) recordables. These numbers measure failures that already occurred. What remains unmeasured are the hundreds of near-misses, unsafe conditions, and developing hazards that frontline workers encounter daily but never formally report.

A facility with zero recordable incidents might appear safe while actually operating with dozens of unaddressed hazards. The absence of reported injuries does not indicate the absence of risk. It often indicates the absence of visibility into actual conditions on the manufacturing floor. Walking the production floor reveals this disconnect immediately. Operators work around frayed cables rather than reporting electrical hazards. Machine guards get temporarily removed to clear jams, then stay removed for weeks.

Key Insight : Management sees safety through metrics showing zero incidents and scheduled walks showing clean floors - neither reveals the hazards workers navigate daily.

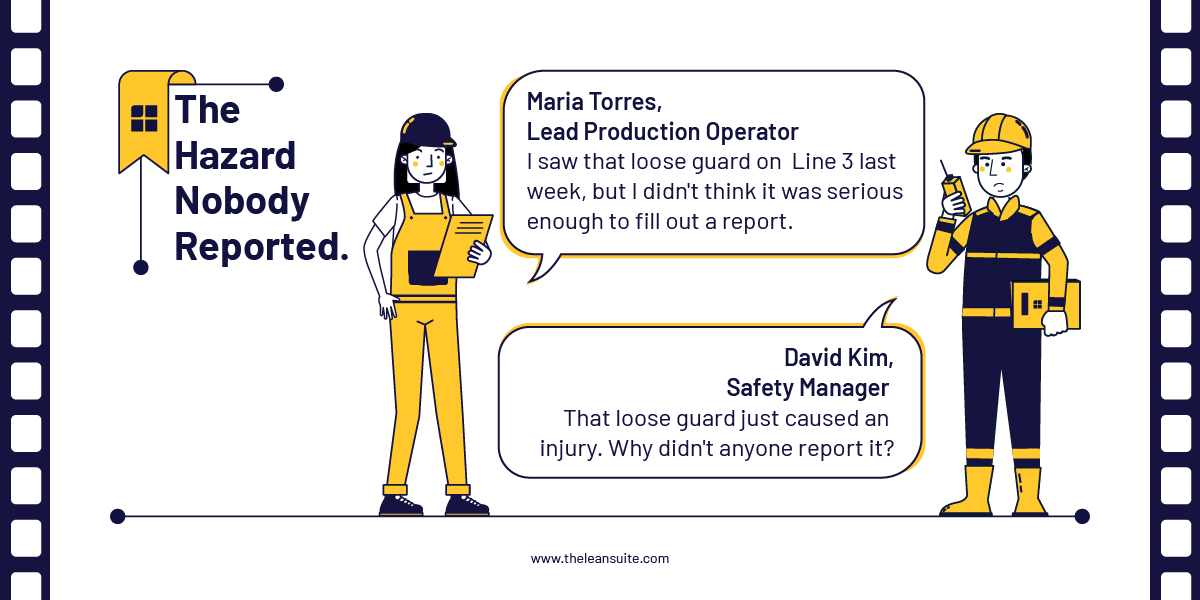

Why Frontline Workers Stay Silent

The decision to report or not report a hazard happens in seconds. A machine operator notices a loose guard. A material handler sees a pallet stacked unsafely. In that moment, multiple factors converge to determine whether the observation becomes a formal report or simply gets filed away mentally. These barriers operate across five distinct dimensions that together suppress hazard visibility.

Fear of Repercussions

Despite safety policies that theoretically encourage reporting, workers often perceive risks to themselves when raising concerns. Reporting a hazard might trigger questions about why they were in that area, whether they followed proper procedures, or how long the condition existed before getting reported. In facilities where safety incidents generate blame rather than investigation, workers learn that reporting creates personal exposure.

Production Pressure Override

Running upstream processes at maximum speed to meet targets makes stopping to document hazards feel impossible. Following through on a hazard report might require shutting down equipment or pausing operations while corrections occur. When supervisors consistently prioritize production over safety reporting, workers receive clear messages about what actually matters.

Perceived Futility

Workers who report hazards but never see corrections stop reporting. If a reported electrical hazard remains unaddressed for months, why report the next one? Facilities with poor follow-through on hazard reports inadvertently train workers that reporting is performative rather than productive. Workers who see their safety concerns ignored begin to view hazards as permanent fixtures rather than correctable problems.

Process Complexity

If reporting a hazard requires finding a specific form, filling out multiple fields, obtaining supervisor signatures, and submitting through designated channels, many observations never make it through this gauntlet. The more steps involved, the higher the barrier to reporting. Hazards get mentally triaged. Only the most severe make it through complex reporting processes while moderate concerns that could prevent future incidents remain undocumented.

Social Dynamics

In tight-knit crews with established norms, being the person who "always reports stuff" can create social friction. Workers worry about being perceived as complainers or troublemakers. This is particularly pronounced in facilities where safety culture remains immature and reporting is viewed as tattling rather than protecting the team.

Key Insight : Five barriers converge in seconds when a worker spots a hazard - each teaching them that staying silent protects them better than speaking up protects the team.

The Paper Trail Problem

Paper-based safety reporting systems appear functional on the surface but create invisible barriers to actual reporting. The physical act of documenting a hazard on paper introduces friction at every step. Organizations recognizing verbal communication limitations often implement these systems as improvements, yet the format itself undermines consistent hazard identification. These barriers manifest across four distinct mechanisms that compound to kill reporting motivation.

Physical and Geographic Barriers

Finding the correct form requires knowing where forms are stored and which form applies to different hazard types. Completing paper forms demands time that competes with production responsibilities. The spatial disconnect between where hazards exist and where they get documented creates additional barriers. A worker identifies a hazard in a remote area of the facility but must travel to wherever safety forms are kept, complete the documentation, then return to their work area.

Accountability Gaps

A completed hazard report goes into a physical inbox or folder. Who received it? When was it reviewed? What actions are being taken? Paper trails provide no inherent visibility into these questions. Workers submit reports into what feels like a black hole. Without confirmation that anyone saw their report or took action, the motivation to report future observations evaporates.

Traceability Failure

The lack of traceability in paper systems enables hazards to fall through cracks systematically. A hazard report can be misplaced, misfiled, or simply forgotten in someone's inbox. There is no automatic escalation for overdue hazards. No notification when assigned personnel fail to address findings.

Pattern Analysis Impossibility

Analyzing patterns across paper safety reports becomes prohibitively difficult. Each report exists as an isolated document rather than a data point in a broader pattern. Identifying that a specific area generates recurring hazards requires manually reviewing stacks of paper reports and looking for commonalities. This analysis rarely happens.

Key Insight : Paper systems trade verbal communication's memory problem for a geography problem - both leave hazards invisible, just through different mechanisms.

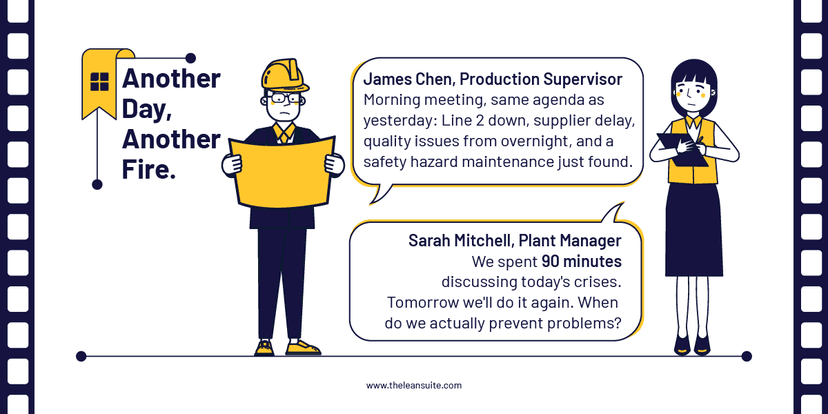

Leadership Blind Spots

Management visibility into actual shop floor safety conditions often relies on aggregated metrics that obscure more than they reveal. Monthly safety reports showing total incidents, near-misses reported, and training completion percentages create an illusion of comprehensive safety oversight. This data-driven approach misses the operational reality that generates risk. Three specific patterns create systematic blind spots in leadership awareness.

Scheduled Walk Theater

Scheduled safety walks follow predictable patterns that enable preparation and concealment. When leadership conducts safety inspections on the same day each month, word spreads in advance. Areas get cleaned up. Temporary fixes get applied. The version of the shop floor that leadership observes differs substantially from conditions during normal operations.

Reporting Chain Filters

Supervisors under pressure to demonstrate good safety performance may downplay concerns or delay reporting hazards until they can simultaneously present solutions. This creates gaps between when hazards emerge and when leadership becomes aware. In this time lag, risks escalate from manageable to serious.

Physical Distance Impact

Executives who spend most time in conference rooms and offices only experience the shop floor during structured visits. They miss the informal observations that reveal actual conditions. The smell indicating a ventilation problem. The workaround that bypassed a safety interlock. The near-miss that operators discussed but never formally reported.

Key Insight : Scheduled safety walks create theater - areas get cleaned before inspections while the version leadership observes differs substantially from normal operations.

The True Cost of Invisible Hazards

Unreported hazards generate costs that remain unattributed to root causes. When a manufacturing facility experiences an injury, investigation focuses on the immediate circumstances of that specific incident. What rarely gets calculated is the cost of the unreported hazards that preceded it. The complete financial impact extends across multiple cost categories that compound over time.

Direct Financial Impact

According to the Bureau of Labor Statistics, the manufacturing sector recorded 408,130 nonfatal occupational injuries and illnesses in 2021. The National Safety Council estimates the average cost of a workplace injury requiring medical consultation exceeds $40,000 when accounting for medical costs, wage replacement, and administrative expenses. Serious injuries requiring hospitalization generate costs exceeding $150,000.

Indirect Cost Multiplier

Indirect costs multiply the financial impact substantially. Production disruption from incidents, investigation time, temporary worker replacement, potential equipment damage, and regulatory compliance activities following serious incidents generate expenses far exceeding direct medical costs. Industry analysis suggests indirect costs typically run three to five times higher than direct costs.

Operational Inefficiency

Unreported hazards create chronic inefficiencies as workers develop workarounds to avoid risks. A machine with an unsafe condition gets operated more slowly. An area with poor lighting receives less thorough inspections. These micro-inefficiencies compound across hundreds of daily decisions, degrading overall operational performance.

Employee Impact

Workers who operate in environments where their safety concerns go unheard become disengaged. Facilities with poor hazard reporting cultures see higher turnover among safety-conscious workers. The employees most likely to identify and report hazards are often the same employees most frustrated by organizations that ignore their observations.

Key Insight : A $40,000 injury represents just the visible tip - the unreported hazard that preceded it generated months of inefficiency, workarounds, and risk exposure that never appears on any cost report.

Breaking Down Reporting Barriers

Reducing friction in the reporting process increases observation documentation exponentially. The goal is making hazard reporting easier than not reporting. Technology and process design can eliminate the barriers that currently prevent frontline workers from surfacing hazards they observe daily. Four strategic interventions address the core friction points that suppress reporting.

Mobile-First Solutions

Workers carrying mobile devices can document hazards at the point of observation. Taking a photo of the hazard and adding a brief description takes seconds. The spatial connection between observation and documentation gets preserved. GPS (Global Positioning System) tagging automatically records location. Time stamps create precise records.

Simplified Information Requirements

Essential elements include what the hazard is, where it exists, and how severe the worker perceives it. Additional fields like detailed descriptions, root causes, and recommended solutions can remain optional. Workers comfortable providing more detail can do so. Workers wanting to quickly flag a concern can submit minimal reports that still surface the issue for follow-up investigation.

Direct Submission Without Gatekeepers

Allowing direct submission from any worker ensures observations reach safety systems without filtering. If a worker must obtain supervisor approval before a hazard report becomes official, observations die before documentation. Supervisors become gatekeepers who may filter reports based on production priorities.

Immediate Confirmation Systems

Automated notifications confirming receipt, providing tracking numbers, and indicating assigned responsible parties show workers their observations matter. Even if correction takes time, knowing someone is accountable for addressing the concern maintains reporting motivation.

Key Insight : When documenting a hazard takes sixty seconds with your phone versus ten minutes finding forms, the friction equation reverses and reporting becomes easier than ignoring.

Building a Culture Where Hazards Surface

Leadership response to reported hazards shapes future reporting behavior more than any policy or training. The first hazard a new employee reports becomes a formative experience. The organizational response to that initial report teaches the worker whether speaking up produces results or creates problems. Cultural transformation requires deliberate attention across four critical dimensions.

Leadership Response Quality

If leadership responds with investigation, transparent communication about findings, and timely correction, that worker learns reporting produces results. If the report disappears into bureaucracy or generates criticism toward the reporter, that worker learns to stay silent. These individual experiences compound into organizational culture.

Recognition and Transparency

Facilities that recognize employees for identifying concerns send clear messages about priorities. Recognition doesn't require elaborate programs. Simple acknowledgment that a worker prevented potential harm by reporting reinforces the value of observation. Publishing updates on hazard resolution, sharing metrics on average time to correction, and communicating openly about challenges maintains credibility.

Retaliation Prevention

Leaders must monitor for subtle retaliation that occurs below policy radar. A worker who reports hazards suddenly receiving less favorable assignments or missing out on overtime opportunities may be experiencing retaliation that discourages further reporting.

Training Evolution

Training must shift from telling workers to report hazards to teaching them how reporting works and showing them past successes. Training that walks through the reporting process, shows real examples of hazards that were identified and corrected, and introduces the people responsible for follow-through humanizes the system and demonstrates its functionality.

Key Insight : A new worker's first reported hazard becomes a referendum on whether the organization wants visibility or theater. The Leadership's response in that moment programs future behavior across the entire workforce.

From Reactive to Proactive Systems

Leading indicators provide insight into safety system health before incidents occur. Rather than measuring injuries that have already happened, facilities can track observation rates, average time between identification and correction, percentage of hazards identified by frontline workers versus leadership, and recurring hazard patterns.

Predictive analytics applied to hazard reporting data identifies high-risk areas before incidents manifest. Analyzing spatial patterns shows which areas generate the most observations. Time-based analysis reveals whether hazard reporting rates vary by shift. Equipment-based analysis identifies assets generating disproportionate safety concerns.

Near-miss investigation and analysis provides the richest source of incident prevention intelligence. Every near-miss represents conditions that could have produced an injury but didn't due to chance. Treating near-misses with the same investigative rigor as actual injuries identifies systemic issues while they remain correctable rather than catastrophic.

Key Insight : Lagging indicators measure how many workers got hurt - leading indicators measure how many hazards got caught before anyone could get hurt.

Making the Invisible Visible

The 78% of manufacturing hazards that go unreported represent the opportunity frontier in safety improvement. Facilities that can surface even a fraction of these invisible risks gain massive advantages in incident prevention.

Technology enables new approaches to hazard identification that bypass traditional reporting psychology. Computer vision systems that identify unsafe conditions, environmental sensors that detect air quality or noise issues, and equipment monitoring that predicts failures before they create hazards provide visibility without relying on worker reporting.

The facility that cracks the visibility problem fundamentally changes its safety trajectory. Instead of reacting to injuries, leadership intervenes on observable precursor conditions. The entire safety operation shifts from lagging to leading indicators, from documentation to prevention, from compliance to genuine risk reduction. Understanding why hazards go unreported is the first step. Acting on that understanding by systematically dismantling reporting barriers and building cultures where visibility becomes normal requires sustained commitment.

Key Insight : The facility that transforms 78% unreported into 78% visible doesn't just prevent injuries - it fundamentally rewrites how safety operates from reactive documentation to proactive intervention

LeanSuite: A complete lean manufacturing software

Schedule Demo